Fact Sheet EVOLON® MASK by Textiles & More

Introduction

Textiles & More has been specialized in development and production of high-quality (interior) fabrics since 2016. Textiles & More introduces effective and fashionable face masks and wants to ensure that everyone in the Netherlands and abroad can feel protected against infections such as Corona, prevent the spread of others, but still want to look fashionable, the EVOLON® MASK.

The EVOLON® MASK are manufactured from a special fabric called “Evolon®”. Textiles & More prints fashionable designs on this fabric. In addition to standard designs, there is the possibility to produce custom-made designs, slogans, emojis and social messages. The designs are printed using transfer sublimation printing. The face masks are washable at a minimum temperature of 60˚ C. Even after many washes, the print retains its quality and appearance.

Tested

Textiles & More has had the masks tested at two test institutes:

– TNO (TNO Reference: MSB-2020-100332199-MHe).

– CENTEXBEL (Centexbel Reference: T2023251 – T&M Facemask Analysis Report 20.06599.01).

Based on these tests, the face masks, in terms of fit, visual inspection, filtration efficiency (more then 90%) and quality retention after use and washing, comply with the European document for non-medical masks published by the CEN (European Committee for Standardization) (CWA-NORM 17553 NORM 2020 Community Face Coverings).

STANDARD 100 by OEKO-TEX® is one of the world’s best-known labels for textiles tested for harmful substances. It stands for customer confidence and high product safety. The Evolon® mask facemasks from Textiles & More are tested by Centexbel (https://www.centexbel.be/nl) and meet the STANDARD 100 of OEKO-TEX® standards.

For more information regarding STANDARD 100 by OEKO-TEX® download the Delaration of Conformity.

Explanation Evolon® – Evolon® material

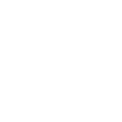

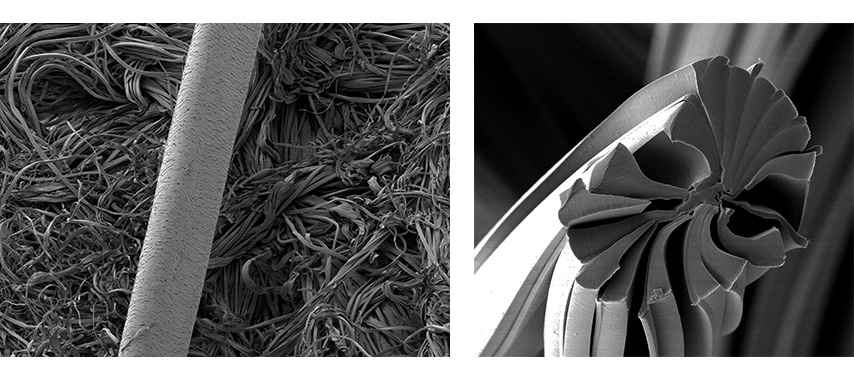

The Evolon® technology is; revolutionary, unique and invented by Freudenberg from Germany. A combination of excellent technical and textile properties within one product. Evolon® fabrics are produced using a unique textile production process invented by Freudenberg. Endless bi-component filaments are spun, laid evenly on a tape, then split into microfilaments and entangled using high pressure water jets to create the final fabric. No solvents or chemical binders are used for this.

Advantages fabric “Evolon®” for EVOLON® MASK

Safe composition

No solvent is used to generate the microfilaments and no chemical binder is used during the Evolon® production process. Evolon® microfilament textile is PVC-free. The Evolon® base fabric is Oeko-Tex 100 product class I certified, which guarantees that they do not contain any substances that are harmful on contact with the skin.

Sustainable

Evolon® textile is a long-life material designed for demanding applications and generates less waste than conventional alternatives. It helps to reduce the impact of waste on our environment. In addition to ISO 14001 certification, the production location of Evolon® microfilament textiles is ISO 50001 certified for its energy management system.

Unique look

Evolon® microfilament fabrics have a unique mat surface in combination with the printing technique and designs of Textiles & More.

Breathable

Evolon® microfilament fabrics are breathable, which means they are permeable to water vapor and air. So, there is no condensation in the mask. This is due to the extremely fine microfilaments, which create millions of “micro” channels through which air can flow. The fabric has a filtration efficiency of at least 90% against airborne particles.

Washable

Evolon® microfilament fabrics are washable. The masks can be washed many times at a minimum temperature of 60 ° C. Even after many washes, the print retains its quality and appearance.

Quick drying

With a very large internal surface in contact with the air, Evolon® microfilament fabrics dry very quickly.

UV protection

Evolon® microfilament fabrics offer excellent UV protection. They have been awarded UV protection factor (UPF) 80, the highest level of UV standard 801. Evolon® microfilament fabrics are made of polyester and polyamide, which provide built-in sun protection. Unlike conventional woven or knitted fabrics, Evolon® textiles have a particularly sleek construction with multi-directional layers that prevent any gaps between fibers. Thanks to this highdensity microfilament structure, Evolon® provides long-lasting protection from the sun, even after washing.

Advantages printing technique Textiles & More

Textiles & More distinguishes itself in the European context in the field of transfer sublimation printing.

Sustainable

The advantage of transfer sublimation printing is the sustainability of the production process because no water is required and the transfer paper is recycled.

Unique look

By means of transfer sublimation printing on the fabric, we achieve a unique look, with bright colors. Every design is possible.

Production

Both the design and production of the face masks are manufactured in our own factory within the EU under our own management. This allows us to optimize quality control.